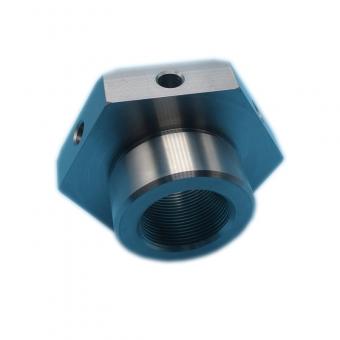

Aluminium Machining Services

As one of the professional aluminium machining parts manufacturers from China, Our has specialized technical experts and a management team to design according to your customized draws and samples, we have rich experience and knowledge for each type of aluminium material characteristics. we manufacture various aluminium parts through the following processes:

Precision machining: Our factory is equipped with various CNC machines, including CNC lathes, turning centers with movable tools, horizontal and vertical band saws, etc. This helps us produce precision aluminum machining parts.

CNC milling and turning: We have several professional 3, 4 and 5-axis machinery, which helps us provide end-to-end CNC milling and turning services.

CNC cutting: Using our high-speed CNC machine allows us to complete projects in a minimal amount of time while providing precision cuts and high yields limiting material waste.

Our Advantages

Excellent Team – One Stop Service.

Quick Responce– Independent research and development of cam design, hardware processing and production, professional metal coating service.

Quality Assurance -We are the ISO9001:2008 qualified factory, To produce the most precious products for our clients

Advanced Equipment – Yijin has a variety of professional CNC machining lathes, high-end testing equipment.

Our Service – We Promised,Provide our service and maintain long-term strategic partnership with customers.

Contact Us Now

We have 15 domestic advanced entire automated productions running water production lines, more than 43 domestic advanced production equipment, mature technology, and work team.

1. According to your design ideas or drawings.

2. We can provide your with the best raw material, excellent price, cost-effective.

3. In strict accordance with ISO quality control Richard, we will strict material control, will purchase of high purity aluminum of raw material of aluminum alloy.

4. We will Formulate a reasonable production plan and establish corresponding follow-up system unification, the responsibility to the person; The delivery date is guaranteed according to customer requirements. Arrange production, urgent order, quick order quick processing, to meet customer urgent supporting production of single/small orders.

5.receive design-design-tool make-produce-post process-surface finish.

6. The products can do all kinds of color or processes depend on your request, such as sandblast and anodize, etc.

русский

русский español

español 中文

中文

Leave A Message

Leave A Message

IPv6 network supported

IPv6 network supported